Macaroni

is one of the most important food industry projects. Macaroni is one of

the most popular food products in the market. The idea of

establishing a specialized factory is a great idea for those who wish

to invest their money in one of the productive projects in general or in

the food industry In particular, we will show the production line of

pasta with the specifications and picture of each stomach, and follow

us.

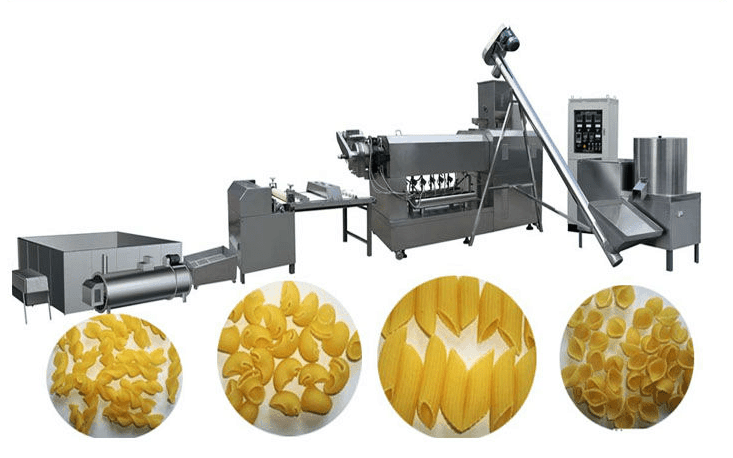

Specifications of macaroni production line:

- The installed capacity is 67 kW.

- Power 45 kW.

- Production line production is 80-120 kg per hour.

- It is 18 meters long.

Components of macaroni production line:

1. Mixing machine:

The

first step in the process of processing pasta and mixing flour or grain

by hand engine is used mainly to mix water, raw materials and other

additives to the product and the rapid integration of materials in equal

quantities and has several advantages, including:

- The mixing machine is about 3 kW.

- Speed up to 365 rpm.

- Production capacity is about 20 kg per batch.

- Dimensions of the machine 1000 * 600 * 900 mm.

2 - spiral lifting machine: -

It is a spiral nail or spiral lift that transfers mixed raw materials to the package. This machine is made entirely of stainless steel stainless steel and has many advantages including:

- Easy to operate.

- Ability to modify runtime.

- The machine is fully automatic.

- The main energy of this machine is 1.1 kW.

- Its production capacity is 100 - 500 kg per hour.

- Dimensions of the machine 1500 * 600 * 2200 mm.

3 - Package: -

- This machine has an extrusion system, a transmission system and a feed system for the material as well as a winding and cutting system as this machine has complete control over the system.

- The frequency of electric motors is adjustable by a power adapter.

- The main functions of the machine start from the extruder where the extrusion and blowing of the material is easy and it is easy to work on this automatic extruder and it is characterized by solidity of performance in the long term.

The package features several advantages including:

- Its primary capacity is 51 kW.

- Production capacity is 80-120 kg per hour.

- Machine dimensions 3000 * 900 * 2000 mm.

4 - Machine pulling and cutting: -

This

machine consists of a part of the pull in addition to a piece of pieces

composed of two pieces together and can cut noodles for different

lengths starting from 30 mm and can be adjusted lengths as needed.

This machine features several advantages including:

- Its core energy is 1.1 kW.

- Production capacity is 100-500 kg per hour.

- Machine dimensions 2300 * 500 * 1100 mm.

5 - transfer machine Snacks: -

It transfers the Snacks from one machine to another and features several advantages including:

- Its main capacity is 0.37 kW.

- The production capacity is 100-500 kg per hour.

- Machine dimensions 2000 * 400 * 1500 mm.

6 - drying machine 3 layers: -

This machine consists of a 3-layer dryer that passes through the snakes and is quick and clean in a clean, non-rustic condition.

This machine features many features including:

- Its primary capacity is 28.1 kW.

- Production capacity 300 kg per hour.

- Machine dimensions 2000 * 500 * 1600 mm.

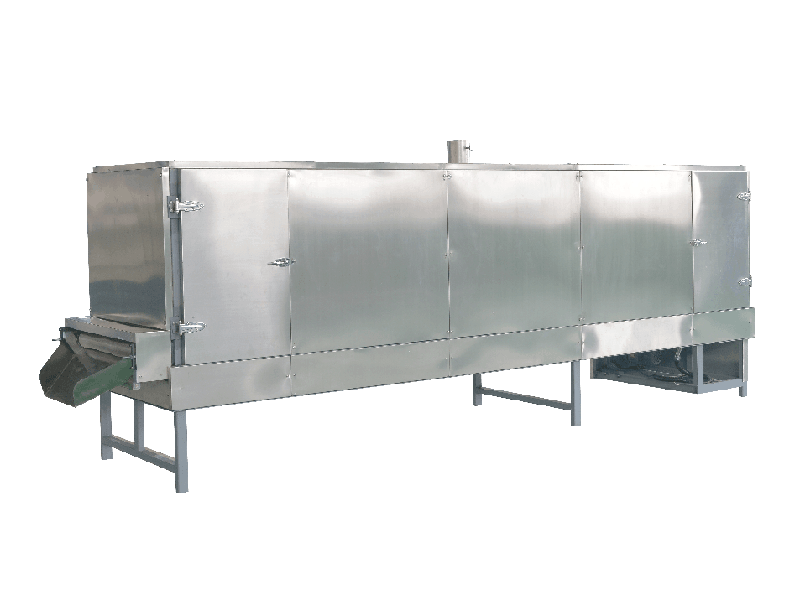

7 - dryer machine recycling: -

- Diesel or gas burner keeps the temperature up or down rapidly with low consumption and high thermal efficiency.

- The structure of the machine is compact as it occupies a small area of the floor with the possibility of output of large production of the machine.

- Ensuring equal moisture in the food where this machine is drying the last piece.

- The presence of a drying device commensurate with the speed of drying all food.

- This machine is suitable for drying twice, especially with materials requiring low temperature and short time to become dry.

This machine features several advantages including:

- Basic energy is 3.33 kW.

- Production capacity is 100-300 kg per hour.

- Dimensions of the machine 7000 * 1600 * 2000 mm.

8 - Refrigerated conveyor machine: -

This

machine is a cooler and an automatic converter for the packing machine

at the same time, which contains three fans and can cool the syncs at

the same time.

This machine features several advantages including:

- Basic energy 1.04 kW.

- Production capacity is 100-500 kg per hour.

- Dimensions of the machine 5000 * 1500 * 400 mm.

9 - Weight packing machine: -

This

machine is packed with high precision especially for fragile materials,

snacks, puff, sweets, sugar, pet foods and some small formulations.

This machine features several advantages including:

- Basic power 2.2 kW.

- Production Capacity 150-1300 ml.

- The speed is 60 ppm maximum.

- The length of the bag is from 50-300 and the width of 60-200.

- The thickness of the film is 0.04 to 0.08 ml.

- Maximum film size is 42 ml.

- The machine weighs 400 kg.

EmoticonEmoticon