The project of production of mineral water is one of the productive projects that a large number of small investors to invest their money in because of the high demand for products provided by the addition of good profit margin that can be achieved from this project other than the ease of work in the project is not as complex as it is The case with some other productive projects that can achieve the same profits or even less than it, and this is based on the desire of a large number of those wishing to invest in this area to know the production line of mineral water, we decided to search and collect information and thanks to God we have reached abundant information about this Line and its specifications and offer it to you during this post.

Mineral water bottling production line:

1- Bottling machine at the beginning of production line :

- The machine is made entirely from the acetanless .

- The operator places the empty bottles randomly in the machine and the machine spits at the beginning of the line .

- There are pockets of stainless steel through which the process of stitching and change depending on the size of the bottle .

- The machine is a 3.25 inch .

- A vacuum pump is attached to ensure the stability of the empty bottle and the walker .

- Stainless steel is manufactured by machine 3 mm .

- The machine operates with a control system .

- The machine engine is a German industry .

- The control panel of the machine is supplied and reduced speed .

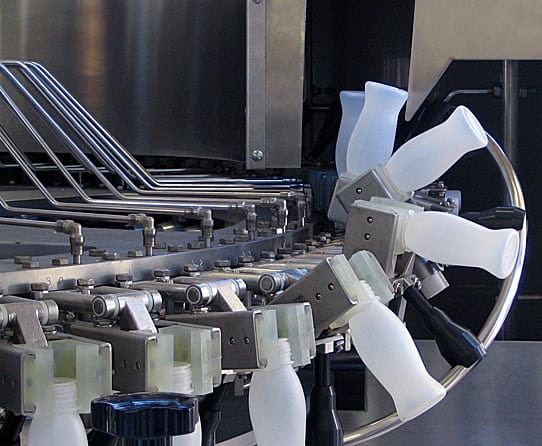

2. Rinser Machine:

- The machine is made entirely of stainless steel.

- The machine is equipped with 24 heads for rinsing .

- The machine rinses bottles with water or any liquid as desired :

- The bottle enters through the Star of Entry, which is made from Artilon food .

- The hyde embraces the bottle from the neck .

- The bottle fluctuates 180 degrees .

- The liquid or water is pumped into the bottle to complete the rinsing process .

- The process of pumping water inside the bottle in the last third of the session is stopped so as to filter the rinsing water inside the bottle .

- The bottle returns to its original position, reverses 180 degrees, and is removed by the exit star made of the artilon food and placed on the walk .

- The machine's head is made of stainless steel and has an artilon stopper that touches the glass .

- There is a valve for the machine that is made of stainless steel and the purpose of running the water pump inside the bottle .

- Walk down and attach a vacuum pump to ensure that the bottle is empty .

- The machine is manufactured from stainless steel .

- The machine is controlled .

- The machine engine is a German industry .

- The control panel of the machine and through it is supplied and reduced the speed of the machine .

3. Filling Machine Filling Machine:

- The machine is made entirely of stainless steel .

- Before packing, pass the bottle on a tunnel with an ultraviolet filter for sterilization .

- The machine has 30 packing houses .

- There is a 300 liter stainless steel water tank attached to the 30 guest rooms .

- Diameter of the tannic 100 cm : 120 cm and the thickness of the hall 10 mm and sides 4 mm height 35 cm .

- By gravity the filling is done .

- Machine 3.38 Inch .

- The bottle enters through the food intake starch .

- The bottle is produced by an exit star made of artilon and placed on a walkway .

- The alkaline tannins are controlled by the size of the bottle .

- The star entry movement is connected with the star movement out with the tannic movement by solid bros .

- The machine operates with a control system .

- The machine engine is a German industry .

- The control panel can supply and reduce the speed of the machine .

4. Machine Capping Machine Capping:

- Made entirely of stainless steel .

- The cover head is made of stainless steel.

- The lid is placed randomly at the top of the machine .

- The lid is automatically lowered from the tuck and in reverse state, it is automatically returned .

- The cover is lowered in a final stream where the cover server for the bottle is automatic .

- A warning is given in the absence of a cover, and in the case of overcrowding, the cover operation is stopped .

- The machine is a 3.25 inch .

- The bottle enters through the food intake starch .

- The exit is done by an exiting star made of glass artilon and put on a walk .

- The elevation and descent of the cap head are controlled by the sensory size and height of the bottle.

- The movement of the star entering and exiting and moving the bottles is connected by solid gears .

- German machine engine .

- The machine operates with a control system .

- The control panel is supplied and reduces the speed of the machine .

5- Label machine:

- The machine is made entirely of stainless steel .

- Contains 6 head .

- The HID consists of two parts that govern the nozzle from the top and part from the bottom of the bottle holder and rotate in two directions .

- Turn around the center of the bottle holder .

- Rotated around the hub of the bottle .

- Hot glue machine .

- The paper shall be placed in the designated space .

- The glue is loosened by placing it in a tank with heaters .

- Tung glue is provided with 3 or 4 mesh or custom-made so as to put the glue on the bottle .

- Digital thermometer for temperature control of glue .

- 3.38- inch Stainless Steel Sink Machine Extension .

- Entry of the bottle through the entry star made of artilon food.

- Place the bottle on a rotating rack .

- Spin the bottle and take the glue from the glue tuck and take the paper from the paper trolley and then pass the brush to ensure the adhesive process properly .

- Graduated by an exit star made of artilon food and placed on the walk .

- It is possible to control the rise and fall of the cap head depending on the size and height of the bottle .

- Connect the movement of the star in and out with the movements of bottles by means of solid gears .

- The machine operates with a control system .

- The machine engine is a German industry .

- The control panel provides or reduces the speed of the machine .

Notes on the mineral water production line :

- Most parts of the city are manufactured by CNC method to ensure complete quality .

- The line is subjected to high levels of protection and protection to protect the personnel and electrical and mechanical equipment attached to the machine :

- The circuitry is designed so that in case of power failure and its return is only in operation .

- The electric panel is equipped with circuit breakers that protect the circuit in the event of a surge .

- The electric panel is equipped with over-load against overload.

- Provide the panel with protection units against voltage increase and decrease .

- The panel is equipped with a circuit controller in the absence of one of the circuit boards .

- The panel is equipped with a unit that protects the engine and the machine in the case of reversing the wave .

- Machine speed is 3000 bottles per hour .

- The size of the bottle to be filled 750 mm : 2 liters .

- 3 year warranty The annual maintenance contract is provided by providing all spare parts after warranty for a material fee .

EmoticonEmoticon